Formlabs Form 4L

Blazing Speed Meets Unmatched Accuracy

Form 4L is a blazing-fast large-format masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. Turn your biggest ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4L ecosystem.

Features

- Fast: Full-size rapid prototyping

- Intuitive: Anyone can learn in 15 minutes.

- Large scale model: Solve big problem with large scale models.

- Reliable: Large format 3D printing You can depend on.

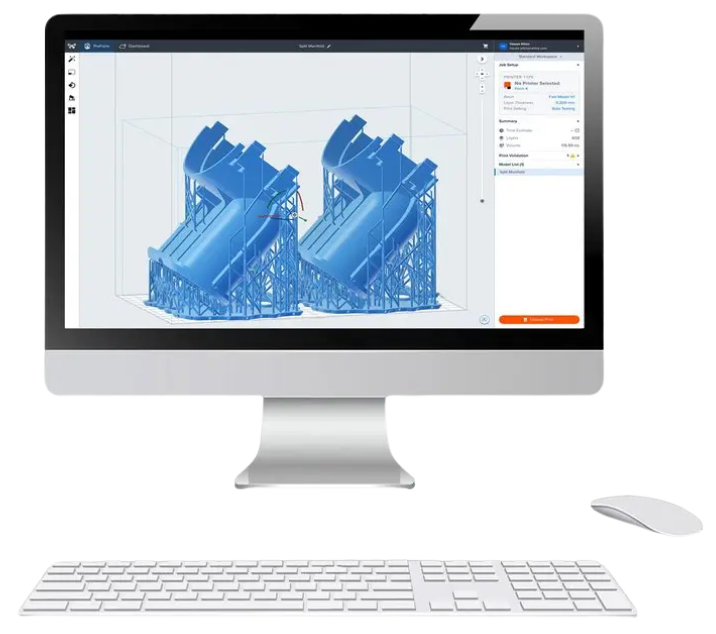

Prepare

Open Formlabs’ PreForm software, import your model, and orient it properly for printing. Add supports if necessary to ensure stability during printing. Select the appropriate resin type and printer model

Monitor your prints and manage your printers from anywhere with an integrated camera, printer diagnostic tools, and our free Dashboard software. Handle the printed part with gloves to avoid contact with uncured resin.

Wash

Place the build platform with the print directly into the Form Wash L. Alternatively, remove the part from the platform and place it in the wash basket. Adjust the time based on the resin type (PreForm will suggest a duration).

Cure

Place the part on the rotating turntable inside the Form Cure L. Use the touchscreen to select the resin type, which automatically sets the temperature and time. Start the curing process. After curing, inspect the part.

Form Wash L

The Form Wash L is an advanced post-processing solution designed for use with large-scale 3D prints, particularly those produced on Formlabs SLA 3D printers like the Form 3L and Form 3BL. It simplifies and automates the washing process, ensuring consistent and efficient removal of residual resin from printed parts.

Form Cure L

The Form Cure L is a professional-grade post-curing device designed to optimize the mechanical properties and finish of large-scale 3D printed parts created using Formlabs SLA printers like the Form 3L and Form 3BL. This curing unit ensures that printed parts reach their maximum strength, accuracy, and durability by completing the polymerization process.

Technical Specifications

| Technology | Low Force Display™ (LFD) |

| Build volume (W x D x H) | 35.3 × 19.6 × 35.0 cm 13.9 x 7.7 x 13.8 in |

| Layer thickness (Z resolution) | 25–200 microns |

| XY resolution | 46 microns |

| Average print speed | 24mm/hr |

| Maximum print speed | 80 mm/hr |

| Resin Tank lifetime | 75,000+ layers with any Formlabs material |

| Printer weight | 58.5 kg | 129 lb |

| Printer dimensions | 66.4 x 52.8 x 79.4 cm 26.1 x 20.8 x 31.3 in |

| Software compatibility | Windows 7 and up Mac OS X 10.12 and up |

| File types accepted | STL, OBJ, 3MF |