In today’s competitive product development landscape, professional prototyping demands speed, precision, material versatility, and reliability. Whether you are in product design, engineering, healthcare, or manufacturing, having the right 3D printer can dramatically reduce time-to-market. This is where Formlabs 3D printers stand out as a powerful solution for professional prototyping.

1. Industry-Leading SLA & LFS Technology

Formlabs specializes in SLA (Stereolithography) and LFS (Low Force Stereolithography) technology, which deliver:

- Ultra-smooth surface finish

- High dimensional accuracy

- Fine feature details

- Tight tolerances for functional parts

Unlike traditional FDM printers, SLA-based Formlabs 3D printers produce parts that closely resemble injection-molded components, making them ideal for client presentations and functional testing.

2. Exceptional Print Quality & Accuracy

Professional prototyping requires precision. Formlabs printers provide:

- Layer resolution as fine as 25 microns

- Consistent repeatability

- Minimal post-processing

- Accurate small features and thin walls

For industries like medical devices, dental applications, and engineering components, this level of precision is critical.

3. Wide Range of Engineering-Grade Materials

One of the biggest advantages of Formlabs 3D printers is their extensive resin ecosystem, including:

- Tough & Durable Resins

- Rigid Resins

- Flexible & Elastic Resins

- High Temp Resins

- Biocompatible Resins

- Castable Resins

This allows professionals to create prototypes that mimic final production materials — whether testing flexibility, heat resistance, or mechanical strength.

4. Fast Turnaround for Product Development

Speed is everything in product development. With Formlabs systems:

- Rapid print cycles

- Batch production capability

- Efficient pre-form software (PreForm)

- Automated resin handling

Teams can iterate multiple design versions within days instead of weeks, accelerating innovation and reducing development costs.

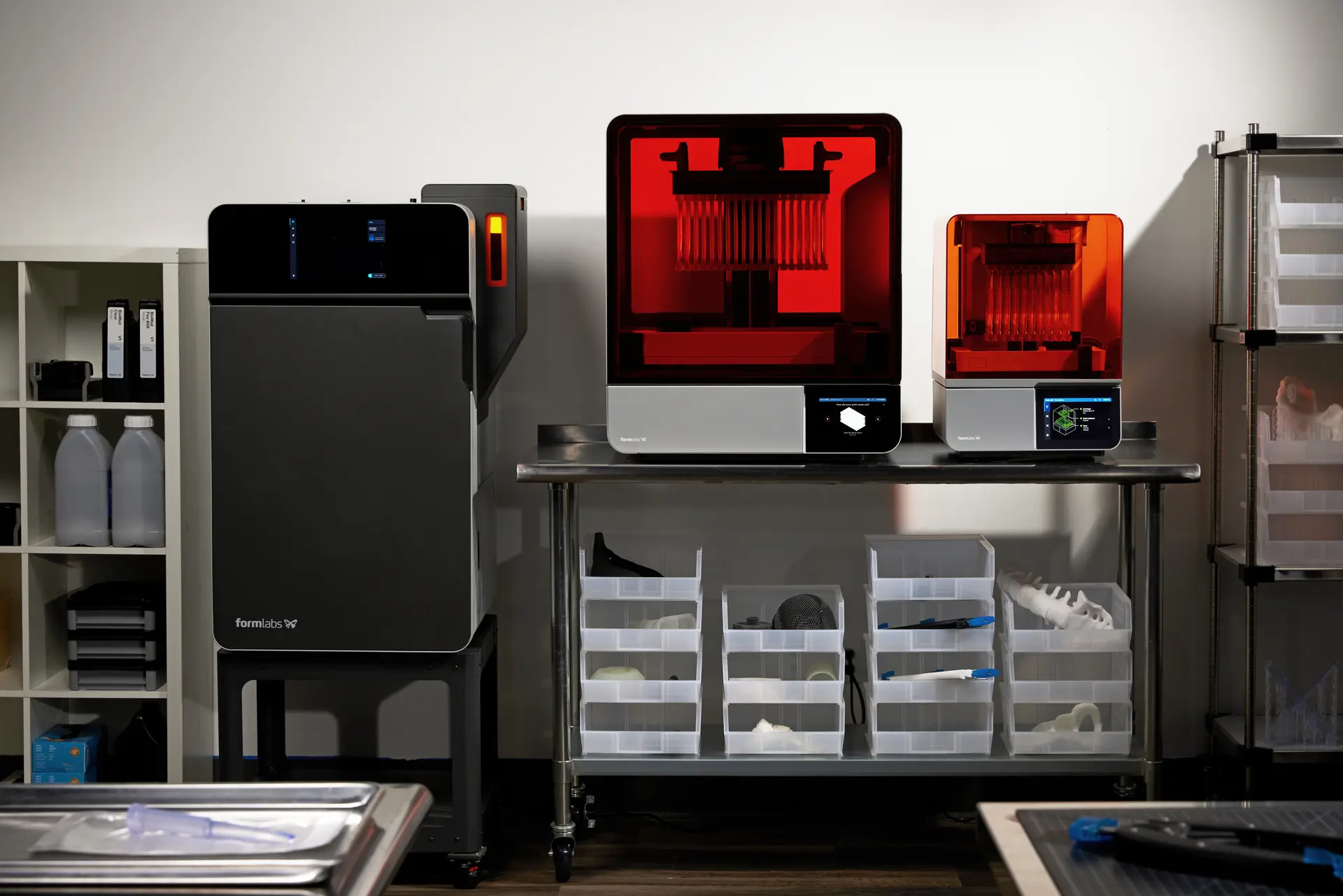

5. Scalable Solutions for Businesses

From desktop units to larger production systems, Formlabs offers scalable options such as:

- Form Series (Professional desktop SLA printers)

- Fuse Series (Selective Laser Sintering systems for nylon parts)

This makes Formlabs suitable for startups, design studios, research labs, and manufacturing companies.

6. Reliable Ecosystem & User-Friendly Workflow

Formlabs provides a complete ecosystem including:

- PreForm software for easy file preparation

- Automated resin systems

- Wash and Cure post-processing units

- Cloud-based print management

This end-to-end workflow reduces errors and ensures consistent professional results.

7. Cost-Effective Professional Quality

Compared to industrial SLA machines costing significantly more, Formlabs 3D printers offer:

- Lower initial investment

- Reduced material waste

- Affordable consumables

- Professional-grade output at mid-range pricing

This balance between performance and cost makes them a top choice for businesses seeking ROI-driven prototyping solutions.

Industries That Benefit from Formlabs 3D Printers

- Product Design & Development

- Automotive Prototyping

- Healthcare & Dental

- Engineering & Manufacturing

- Education & Research Labs

Final Thoughts

If your business requires high-precision, functional, and presentation-ready prototypes, Formlabs 3D printers provide the ideal balance of accuracy, material versatility, speed, and cost-efficiency. Their advanced SLA technology and robust ecosystem make them one of the most reliable solutions for professional prototyping in 2026 and beyond.

For companies looking to reduce development cycles and enhance innovation, investing in Formlabs 3D printers is a strategic move toward faster and smarter product development.

Products we offer at Ashtech 3D Innovations in Pune, Mumbai, Nashik, Aurangabad, Nagpur, Kolhapur, Goa, Belagavi, Vishakhapatnam, Guwahati, Chhattisgarh, Delhi, Vadodara, Faridabad, Bangalore, Thiruvananthapuram, Chennai, Hyderabad, Ahmedabad

Zortrax FDM 3D Printer (M300 Dual,M300 Plus, M200 Plus), Formlabs SLA 3D Printer (Form 4, Form 4L,Form 4B, Form 4BL), Thor 3D Scanner (Calibry, Calibry Mini). FDM 3D Printing Services, SLA 3D Printing Services, SLS 3D Printing Services, MJF 3D Printing Services, Metal 3D Printing Services, Vacuum Casting Services , 3D Scanning Services, Reverse Engineering Services & All Type Of Prototyping Services.