Ashtech 3D Innovations

A Leading Supplier of 3D Printers, 3D Scanners & CAD / CAM / CAE Software in India.

Additive Manufacturing Technologies & Reverse Engineering Solution

Our strengths allow us to help industries optimize their product design, engineering processes thereby making them more innovative, efficient, cost effective and time saving. Our premium partnerships With Zortrax, Formlabs and Calibry. We deliver unparalleled precision, efficiency and reliability in 3D printing and 3D Scanning technology.

Prominent Customers

About Us

Welcome to Ashtech 3D Innovations, your trusted partner in advanced 3D printing solutions. Established with a vision to revolutionize manufacturing and prototyping, we specialize in providing state-of-the-art 3D printers, catering to industries ranging from engineering design to healthcare, education and beyond.

At Ashtech 3D Innovations, we are proud to be associated with leading global brands like Zortrax (FDM 3D Printer), Formlabs (SLA & SLS 3D Printer), Calibry (3D Scanners) and Siemens delivering cutting-edge technologies that empower innovation and creativity. Our product line includes a diverse range of 3D printers, 3D Scanners, filaments, resins and accessories designed to meet the unique needs of every client.

With years of expertise, we not only provide high-quality products but also offer end-to-end support, from installation and training to maintenance and technical assistance. Our mission is to enable businesses and individuals to unlock the potential of 3D printing, turning ideas into reality with precision and efficiency.

Whether you’re a seasoned professional or just beginning your 3D printing journey, Ashtech 3D Innovations is here to guide and support you every step of the way.

Brands we represent in India

Zortrax is the Poland based desktop FDM 3d printer brand. Versatile & most reliable for all your 3d printing needs. Zortrax won the World’s Best Desktop 3D Printer by 3D Hubs Community & over 10+ awards in past.

Formlabs is the largest supplier of professional SLA and SLS 3D printers in the world. Formlabs founded in 2011 and develop the first desktop-sized, easy-to-use and affordable SLA and SLS 3D printer with the time.

Calibry is the 3D scanner brand meant to capture objects from 30cm – 10m in length. Calibry is known for its small size and incredible speed. Calibry is most trust Worthy 3D Scanner Brand across in 50+ Countries

The award-winning NX software helps designers and manufacturers deliver better products faster using powerful, integrated CAD and CAM solutions that realize the full value of the digital twin.

Why Choose Us?

- Top-Tier Products: Access to the most advanced and reliable 3D printing technologies.

- Comprehensive Support: Personalized assistance to ensure you get the most out of your investment.

- Industry Expertise: Decades of experience in 3D printing, ensuring quality and innovation.

Let’s create something extraordinary together. Explore the limitless possibilities of 3D printing with Ashtech 3D!

ZORTRAX - Workhorse FDM 3D Printers

Zortrax was founded by Rafal Tomasiak and Marcin Olchanowski. Their goal was to create a complete FDM 3D printing ecosystem, setting themselves apart from the DIY market. Zortrax is a Polish developer renowned for its comprehensive FDM 3D printing solutions. The company offers high-quality FDM 3D printers, dedicated filaments, Z-SUITE software and additional devices to streamline the FDM 3D printing process and post-processing.

Zortrax focuses on delivering precision and reliability in FDM 3D printing, catering primarily to business professionals. At the same time, its products’ ease of use, affordability, and innovative design make them an excellent choice for individual users, including prosumers and hobbyists seeking advanced FDM 3D printing capabilities.

Zortrax products are trusted worldwide in industries like automotive, aerospace, architecture, engineering, industrial prototyping, healthcare and fashion. These sectors benefit from Zortrax’s advanced 3D printing technologies, which enable the creation of precise, innovative designs.

- The Zortrax M200 was launched in 2013 with build volume of 200x200x180 mm and named the Best 3D Printer in the Plug’n’Play Category by 3D Hubs in 2014, reflecting its user-friendly design and superior performance. That year, the Zortrax M200 FDM 3D Printer was voted the 3rd Most Wanted 3D Printer by the 3D Hubs Community, illustrating its widespread popularity.

- It was also recognized as the Best Plug&Play 3D Printer in both 2015 and 2016 and crowned the World’s Best Desktop 3D Printer by the 3D Hubs Community. The Zortrax M200 earned the title of 2nd Best Overall FDM 3D Printer in the 3D Printing Shootout conducted by Make Magazine in 2015. Later Zortrax M200 was upgraded to Zortrax M200 Plus with enhanced capabilities & 4″ IPS touchscreen display.

- In 2016, Zortrax launched the M300, followed by the M300 Plus. The M300 Plus features a large build volume (300x300x300 mm) and a heavy-duty enclosed frame for reliability.

- In 2019, Zortrax released M300 Dual FDM 3D Printer with Dual extrusion technology to simultaneously print with base and water soluble filaments in large build volume 265 X 265 X 300 mm workplace

- In 2020, Zortrax collaborated with the European Space Agency to develop technology for producing 3D-printed composite parts using PEEK filament blends and launched Zortrax Endureal an Industrial 3D Printer.

- The Zortrax Speed Mode, which is dedicated to Zortrax M200 Plus, Zortrax M300 Plus, and Zortrax M300 Dual 3D printers, is available in the Print Speed Adjustments tab that will appear in each printer’s menu after you carry out a standard firmware update.

- With a few parameters that you can change before or during the printing, you can easily control the 3D printing speed and complete your projects up to 3 times faster.

Formlabs - Best in class SLA & SLS 3D Printers

Formlabs was founded by Maxim Lobovsky, Natan Linder, and David Cranor, who met as students at the MIT Media Lab while taking a class called “How to Make (almost) Anything”. The founders also drew on their experience with MIT’s Center for Bits and Atoms Fab Lab program, as well as Lobovsky’s experience with the Fab@Home project at Cornell University.

Formlabs was officially founded in September 2011 to develop the first desktop-sized, easy-to-use, and affordable stereolithography (SLA) 3D printer. Formlabs received early seed funding from investors including Mitch Kapor, Joi Ito, and Eric Schmidt’s Innovation Endeavors. Formlabs pride on bringing new innovative SLA & SLS 3D printing technologies to market to help customers design better products, improve manufacturing processes, and provide personalized care to patients.

Mapping Out Milestones

- In October 2012, Formlabs publicly announced its first product, the Form 1 SLA 3D printer

- In 2014, Formlabs released the Form 1+ SLA 3D Printer, which replaced the Form 1 in their product line.

- In 2015, Formlabs announced the Form 2 SLA 3D printer, including a larger build volume and a wiper. It also switches to a cartridge resin system, instead of bottles that needed to be manually poured into the Form 1 & Form 1+. Third-party resins can be used with Open Mode.

- In 2017, Formlabs announced the Form Wash and the Form Cure. Together with the Form 2, they complete the SLA engine. The Form Wash is a washing machine used to automatically clean liquid resin from printed 3D models. The Form Cure is an ultraviolet postcuring system

- In 2017, Formlabs announced the Fuse 1, a selective laser sintering (SLS) 3D printer. It has a much larger build volume than the Form line of 3D printers, a removable build chamber, and uses nylon powder.

- In 2019, Formlabs announced the 3rd Generation of their SLA printers, the Form 3, form 3B and Form 3L, designed for use by artists, designers, and other professionals.

- In 2020 form labs launched Form 3BL, which features the larger platform of the Form 3L, along with the material capabilities of the Form 3B

- Fuse 1+ was launched in 2021 later on Formlabs launched the Fuse 1+ 30W SLS 3D printer in 2022. It’s an industrial selective laser sintering (SLS) 3D printer.

- In 2024, Formlabs announced its fourth-generation SLA 3D Printer the Form 4, Form 4L, Form 4B & Form 4BL

- Fast Company’s Most Innovative Companies list: Formlabs was ranked #5 in the Manufacturing category for 2024

- Fast Company’s World Changing Ideas Awards: Formlabs and Hasbro’s Selfie Series received an honorable mention in the consumer products category for 2023

- 3D Printing Industry Awards: Formlabs Form 4 won the award for Desktop non-FFF 3D Printer of the Year in 2024

- TCT Hall of Fame: Formlabs CEO Max Lobovsky was inducted into the TCT Hall of Fame

- Formlabs Impact Award: In 2022, the award was given to Andrew Bergeron and James Crigger, scientists at Canadian Nuclear Laboratories

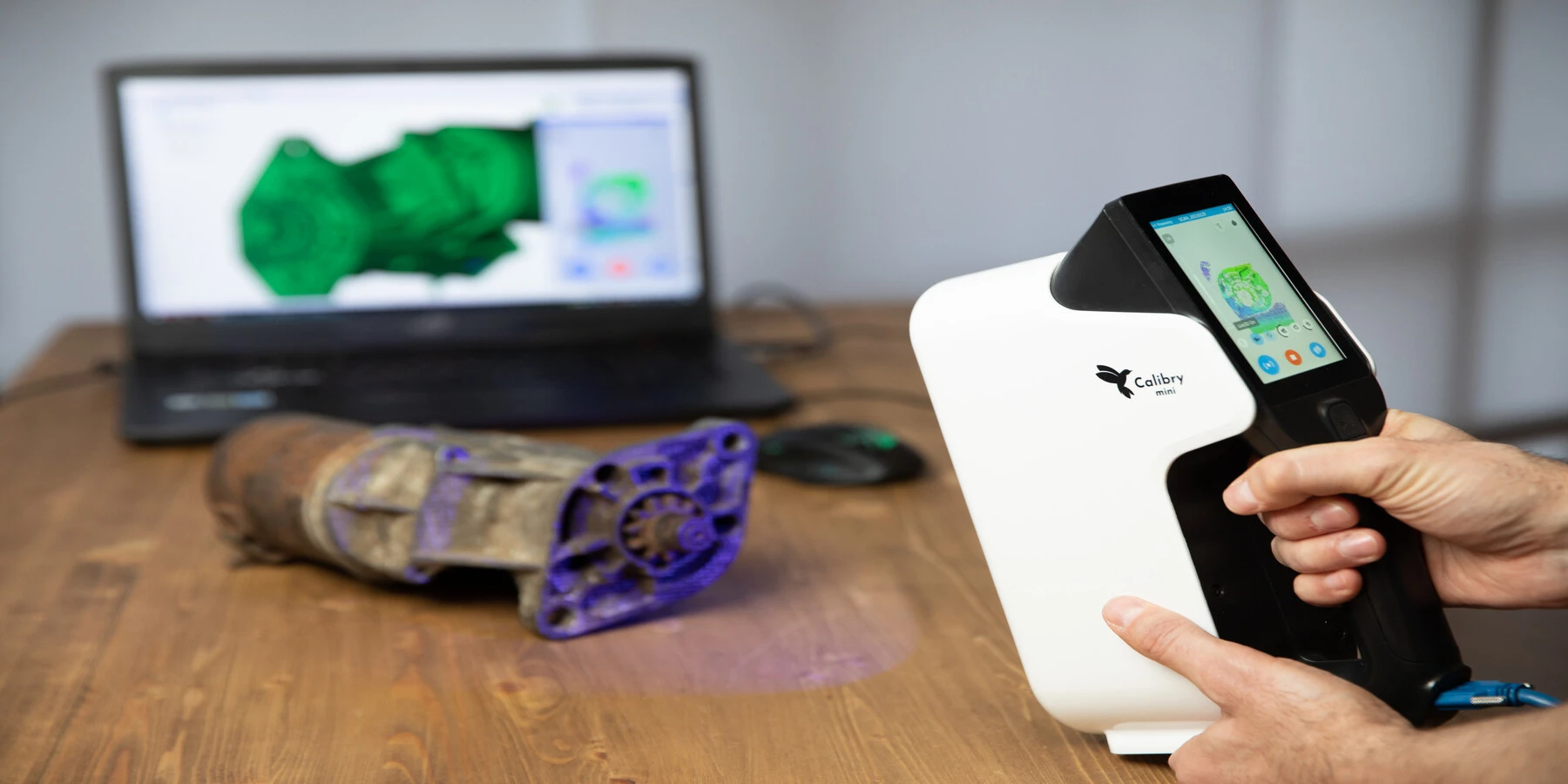

Calibry - Best & Affordable 3D Scanner

The Calibry 3D Scanners are a line of innovative handheld 3D scanners developed by Thor3D, a company known for creating accessible and portable 3D scanning solutions. The Calibry series was designed to cater to professionals and industries requiring high-accuracy 3D data capture for applications such as reverse engineering, 3D printing, and digital modeling.

The Calibry Mini was officially launched in 2020 as a high-precision, handheld 3D scanner aimed at capturing small and complex objects with exceptional accuracy. The Calibry series quickly gained global recognition for its cost-effectiveness and high performance in capturing accurate 3D scans.

Industries such as automotive design, architecture, and education adopted the scanners to streamline 3D workflows. The Calibry 3D Scanners represent Thor3D’s commitment to innovation and accessibility, delivering powerful 3D scanning solutions to professionals across diverse industries.

Key Features:

At just 900 grams, the Calibry was one of the lightest scanners in its category. It could scan objects ranging in size from 20 cm to 10 m, making it suitable for diverse applications, including industrial design and heritage preservation.

The scanner came with user-friendly software Calibry Nest Software for post-processing and creating high-quality 3D models.

Key innovations included:

- User-Focused Design: Lightweight and ergonomic for comfortable, long-duration use.

- Wide Application Range: Scans objects of all sizes, from small artifacts to large industrial components.

- Real-Time Data Capture: Offers real-time feedback on scan quality and geometry coverage.

- Post-Processing Tools: Includes advanced software for refining meshes, optimizing models, and exporting them for 3D printing or CAD integration.

Siemens NX - Best CAD/CAM/CAE Software

- Siemens NX (formerly known as Unigraphics NX) is a high-end integrated software suite for product design, engineering analysis, and manufacturing.

- It is widely recognized for its advanced capabilities in Computer-Aided Design (CAD), Computer-Aided Engineering (CAE), and Computer-Aided Manufacturing (CAM).

- Siemens NX is used across various industries, including aerospace, automotive, electronics, and consumer goods, to design complex products and streamline development workflows.

Siemens NX supports a range of processes, including:

- 3D modeling and drafting

- Simulation and validation

- Tooling and machining

- Additive manufacturing

- Digital twin creation

This comprehensive software offers scalability and flexibility, enabling collaboration across different teams and ensuring high precision in product lifecycle management (PLM). Siemens NX is a preferred choice for organizations aiming to optimize their product development life cycle and the future of manufacturing. Key Features of Siemens NX

- Synchronous Technology: Combines the benefits of parametric and direct modeling, enabling fast and flexible design changes.

- Convergent Modeling: Supports hybrid modeling workflows by seamlessly integrating mesh-based and solid geometry.

- Advanced Simulation: Provides tools for structural, thermal, and fluid flow analysis.

- Manufacturing Integration: Offers end-to-end solutions from design to production, including CAM and additive manufacturing capabilities.

- Collaborative Design: Integrates with Teamcenter for efficient collaboration and data management.

Share your design & we will print precise models for you…

What is 3D Printing?

3D printing technology refers to the process of creating three-dimensional objects using computer-aided design (CAD) files. Unlike traditional manufacturing methods, 3D printing builds objects layer by layer, making it possible to create intricate designs with precision and reduced waste. 3D Printing is applicable for the industries like Automotive, Aerospace, Manufacturing, Prototyping, Consumer Goods and Education.

3D Printing Technologies:

- FDM 3D Printing

- SLA 3D Printing

- SLS 3D Printing

- MJF 3D Printing

- DMLS 3D Printing

Why 3D Printing?

3D printing offers a quick and cost-effective approach to designing and producing parts. Since the need for tooling is eliminated, product teams can significantly accelerate product development cycles. The ability to produce designs quickly gives designers greater flexibility when testing multiple design options. Earlier, when two-dimension printing was introduced to the world, it was wonder to the world. Later, colour printing came up. Slowly, three-dimension printing opened its new arenas to the world. A technology wherein you can print objects. Earlier, it was difficult to believe. Today, despite the slightly higher 3D printing price in India, 3D printing technology is benefiting many sectors like automobile, engineering, mechanical, medicine, architecture, gaming and education among others. It has reshaped the role of manufacturing for many companies through rapid prototyping. Many designers and engineers have been using 3D printing for their work which is making their work easy and giving them wider scope for experimentation.

We have reliable workplace to print/manufacture high-quality components compatible with a wide range of filaments & resins due to which we provide best 3D Printing services in Pune.

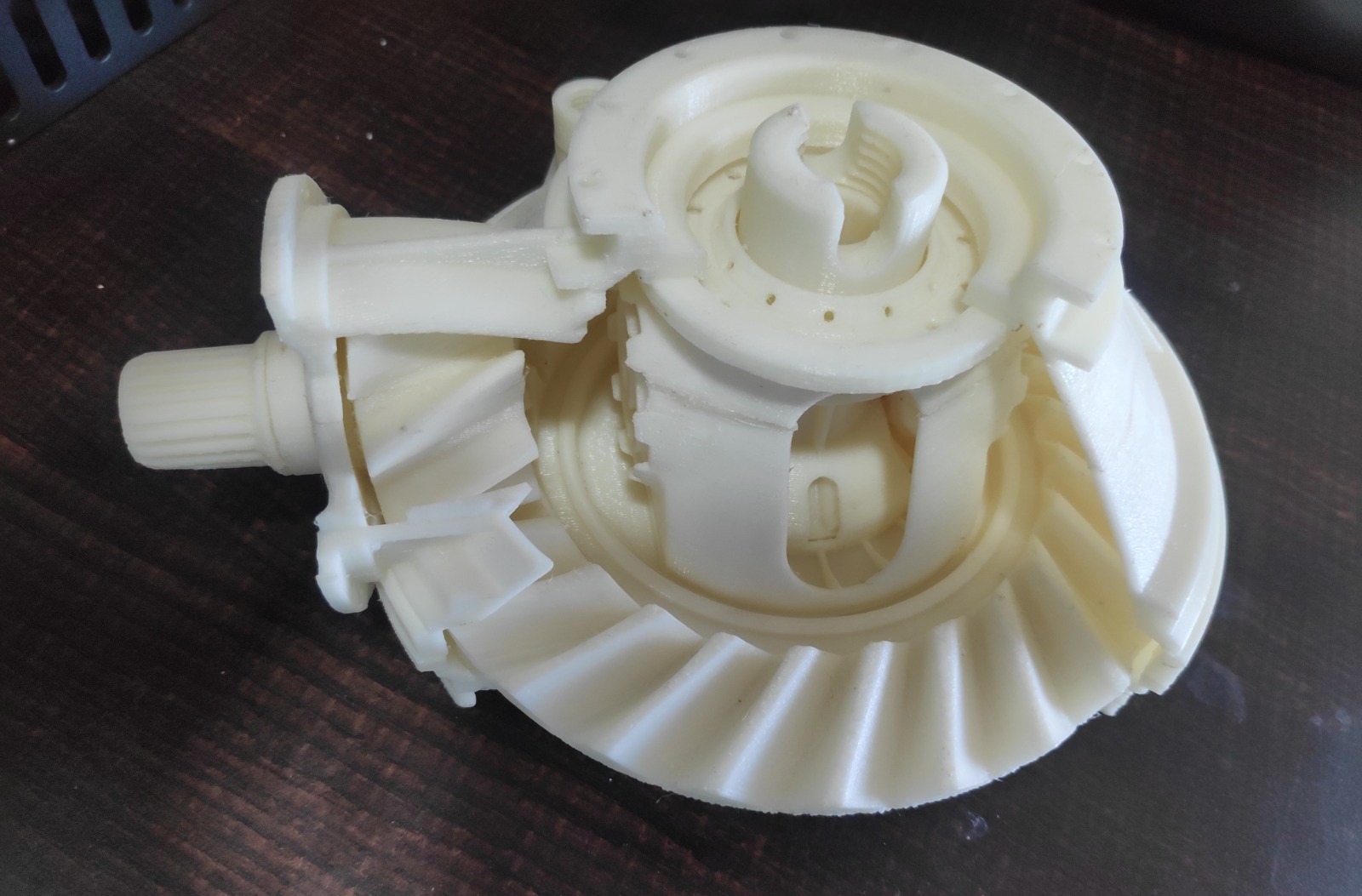

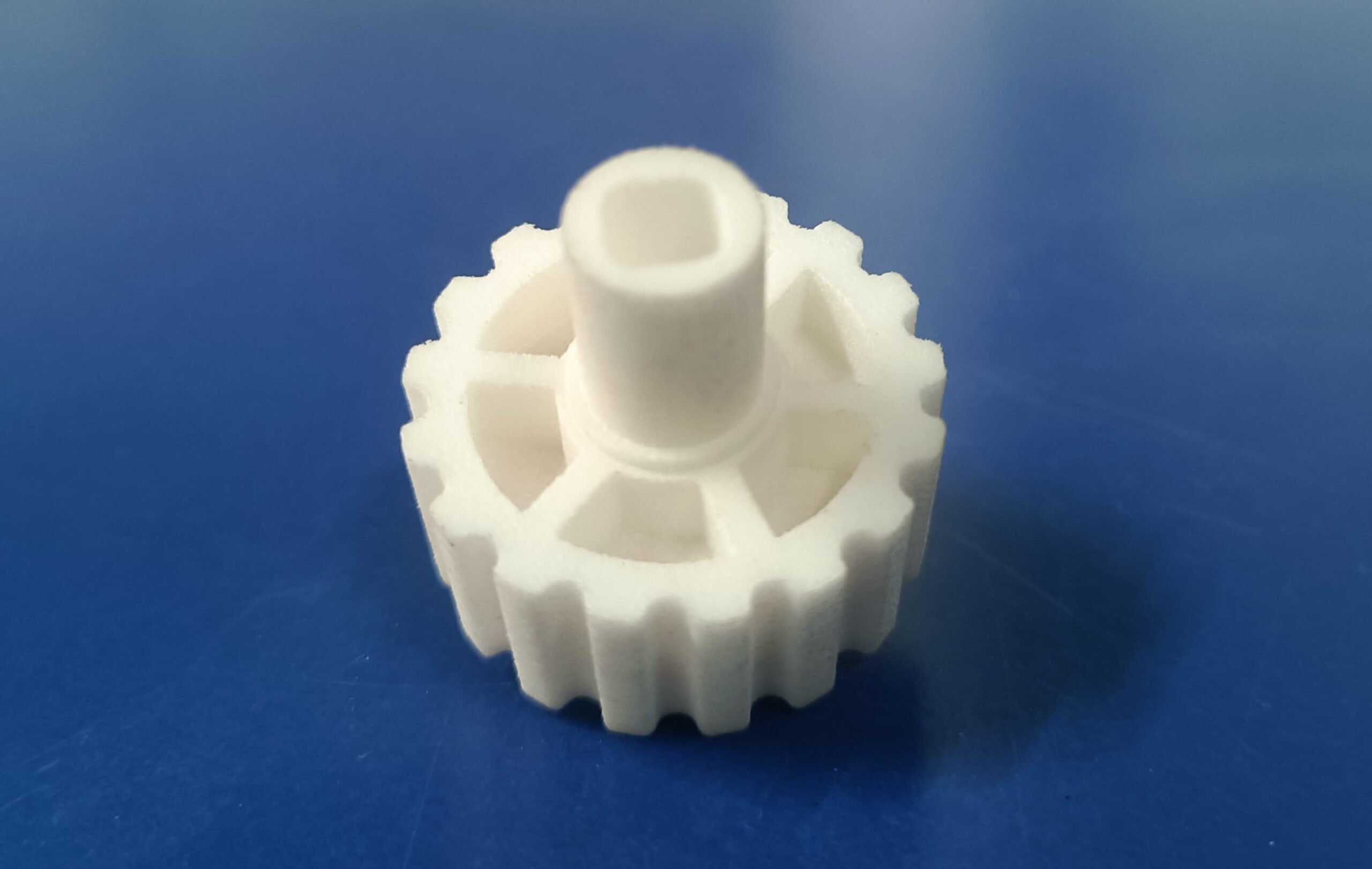

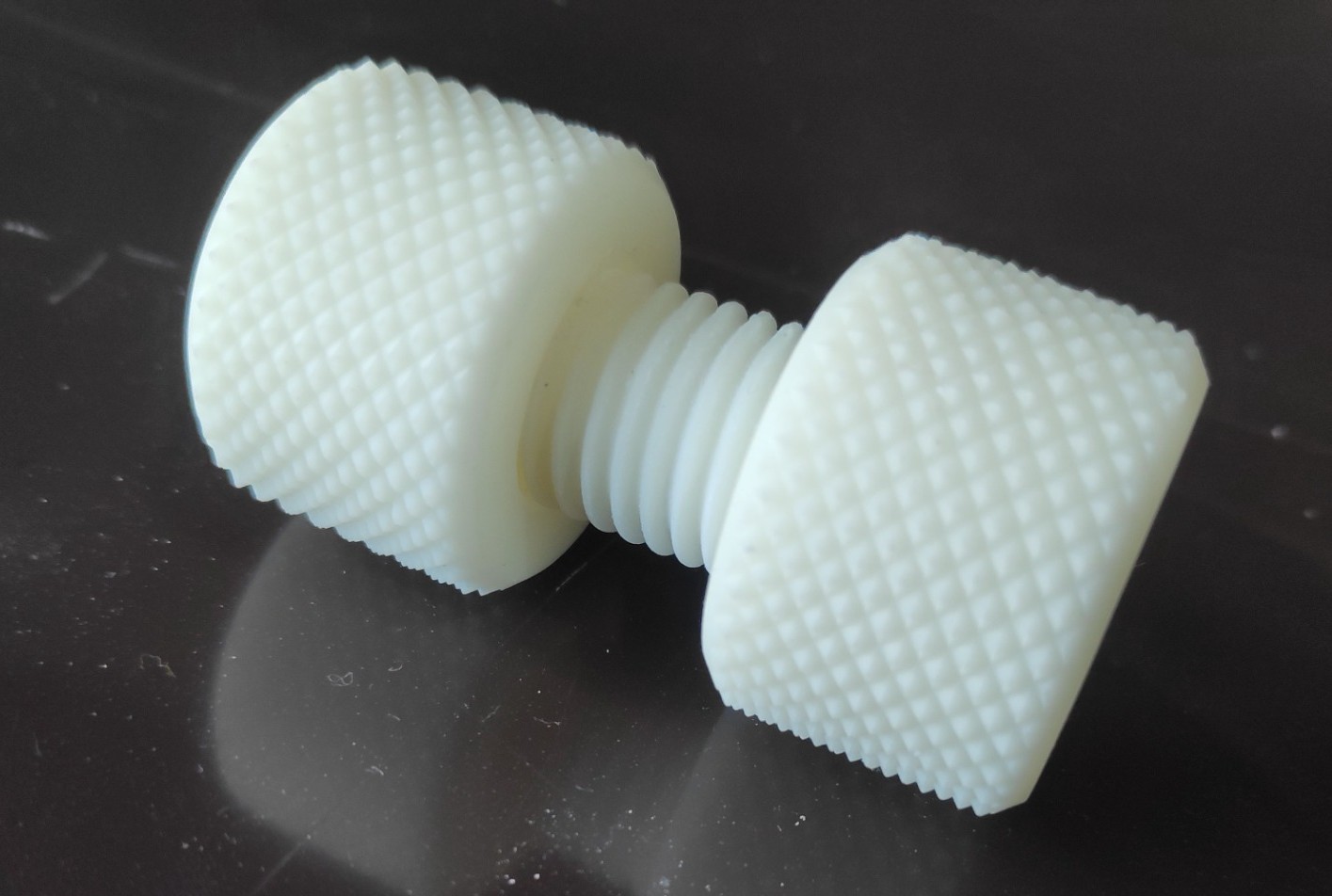

FDM 3D Printing services

Our Fused Deposition Modeling (FDM) 3D Printing technology ensures precise, cost-effective solutions for rapid prototyping and batch production. Explore the possibilities with diverse materials such as ABS, ASA Pro, ESD, HIPS, PLA, Nylon, TPU, PC, PETG and composite materials like Carbon fiber. Elevate your projects with our expertise in additive manufacturing — contact us for cutting-edge 3D printing services in Pune tailored to your needs.

SLS 3D Printing Services

Selective laser sintering (SLS) is a 3D Printing technique that uses a laser as the power and heat source to sinter powdered material typically nylon or polyamide (PA6, PA12, PA66) SLS is considered as fastest process for 3D printing services functional, durable, prototypes or end user parts. Parts possess high strength and stiffness & good chemical resistance. Also we offer Nylon material and Nylon + 30% Glass filled material with SLS technology.

SLA 3D Printing Services

Stereolithography (SLA) 3D Printing technology can 3D print parts with small features, tight tolerance requirements, smooth surface finish & high accuracy parts. It is mainly useful for functional testing and for rapid prototyping. We offer various resins for different applications. We offer wide range of color and various resin material like transparent, flexible, good strength to sustain load to suite customers requirements. SLA 3D printing services in Pune are applicable for Automobiles, Aerospace, Electronics, Medical, Dentistry and Packaging etc.

MJF 3D Printing

Multi Jet Fusion (MJF) is a powder-based 3D printing process that produces high-resolution and precise 3D objects with low porosity and high surface quality. In contrast to selective laser sintering (SLS), in MJF inkjet print head prints components by applying two different binder fluids to the surface of the powder bed (PA12). For best quality MJF 3D Printing services in Pune contact us.

Our Articles

Guide to the Resin 3D Printer: SLA vs MSLA Technology

Resin 3D printing is one of the leading adapted 3D Printing technologies in recent years for producing highly detailed 3D parts. The technology is useful for rapid prototyping, rapid tooling, manufacturing aids and even end-use parts due to high accuracy, fast...

Zortrax Endureal is the New Industrial-Grade 3D Printer

Ready to take your 3D printing to the next level? The Zortrax Endureal tackles the trickiest industrial jobs. It's built for engineers, designers, and manufacturers who need reliable, high-performance results. This printer delivers. It conquers challenges with ease....

Filaments: New applications in the Zortrax FDM 3D Printers

Zortrax FDM 3D Printers are best 3D printers with industry and Third party materials. Zortrax is a top FDM 3D Printer manufacturing company. It is Poland Based Company. Zortrax FDM 3D printers are renowned for their precision, durability and material versatility. With...

Contact Us

ASHTECH 3D INNOVATIONS

Visit Us

102-B Wing, 1st Floor, Parvati Heights, Landewadi Chowk, Bhosari, Pune – 411039.

Call Us

+91 90040 78408

Mail Us

sagar@ashtech3d.com