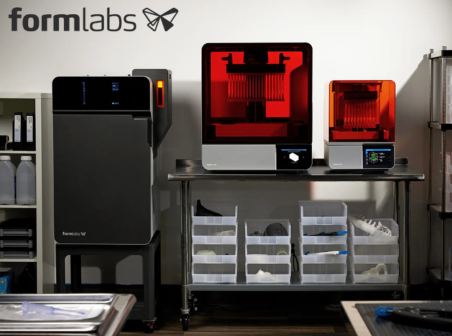

Formlabs is amongst one of the largest SLA and SLS 3D Printer brand. Formlabs builds the tools that make it possible for anyone to bring their ideas to life. In 2011, three MIT graduate students built the first 3D printer that could achieve industrial, professional part quality at an affordable price. Through continuous commitment to innovation, Formlabs has become the largest supplier of professional stereolithography (SLA) and selective laser sintering (SLS) 3D printers in the world. The company develops and manufactures 3D printers and related software and consumables.

It raised nearly $3 million in a Kickstarter campaign and created the Form 1, Form 1+, Form 2, Form Cell, Form 3, Form 3L, Form 4, Form 4B, Form 4L, Form 4BL, Fuse 1, Fuse 1+ and Form Auto Stereolithography (SLA) and Selective Laser Sintering (SLS) 3D printers and accessories.

History of Formlabs:

Formlabs was founded by Maxim Lobovsky, Natan Linder, and David Cranor, who met as students at the MIT Media Lab while taking a class called “How to Make (almost) Anything”. The founders also drew on their experience with MIT’s Center for Bits and Atoms Fab Lab program, as well as Lobovsky’s experience with the Fab@Home project at Cornell University. Formlabs was officially founded in September 2011 to develop the first desktop-sized, easy-to-use, and affordable stereolithography (SLA) 3D printer. Formlabs received early seed funding from investors including Mitch Kapor, Joi Ito, and Eric Schmidt’s Innovation Endeavors. Formlabs pride on bringing new innovative SLA & SLS 3D printing technologies to market to help customers design better products, improve manufacturing processes, and provide personalized care to patients.

Key Features of Formlabs 3D Printers

1. Advanced Stereolithography (SLA) Technology

- Formlabs SLA printers, like the Form 4+ and Form 4L, use SLA technology for high-precision resin-based printing.

- Offers smooth surface finishes, fine details, and excellent accuracy, making it ideal for dental, engineering, jewellery, and medical applications.

2. Selective Laser Sintering (SLS) Printing

- The Fuse 1+ 30W is an SLS 3D printer that enables durable and strong parts using nylon powder, without the need for support structures.

- Great for functional prototypes, low-volume production, and industrial applications.

3. User-Friendly Workflow

- Easy-to-use Preform software allows for automatic print preparation and optimization.

- Dashboard cloud system enables remote monitoring and management of print jobs.

- Quick material switching and automated resin handling for smooth operations.

4. Wide Range of Materials

- Supports a variety of engineering resins, dental resins, castable resins, biocompatible materials, and nylon powders for diverse applications.

- Specialized materials like Tough 2000, Elastic 50A, and Flexible 80A provide flexibility, durability, and strength for different industry needs.

5. Scalability & Production-Ready Solutions

- Form 4L and Form 4BL offer large build volumes for printing bigger models.

- Automation solutions like Form Auto, Fleet Control, and High-Volume Resin Systems enhance efficiency for mass production.

6. Post-Processing Solutions

- Form Wash and Form Cure automate cleaning and curing for better part quality and consistency.

- Fuse Sift and Fuse Blast provides a complete SLS powder recovery and management system.

Products Heighlights:

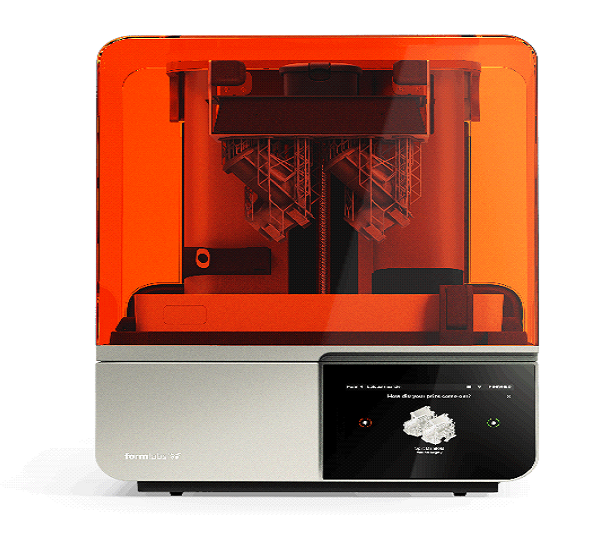

1. Formlabs Form 4

Formlabs Form 4 is a blazing fast masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. Turn your ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4 ecosystem.

- Fast: Most prints in less than 2 hours

- Versatile: Advanced materials for any application.

- Reliable: Unmattched print success rate.

- Intutive: Learn in 15 mins

- Accurate: Rivals injection molded parts.

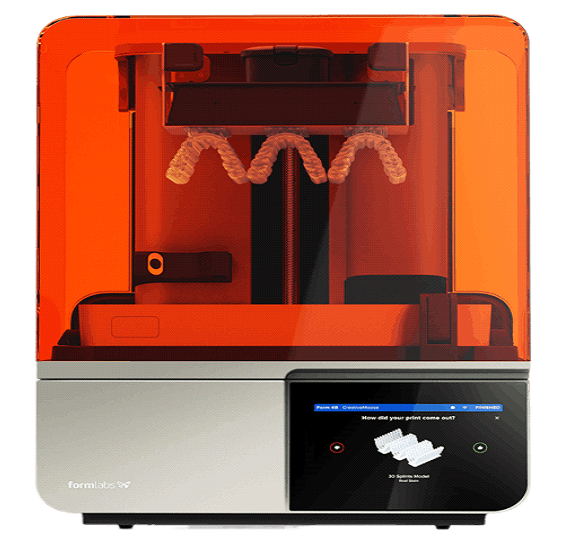

2. Formlabs Form 4B

Formlabs Form 4B is a blazing fast dental 3D printer that offers the most diverse materials library for dentistry and orthodontics. Create high-quality dental models and biocompatible appliances fast, with easy workflows, leading reliability, and stunning part quality using the Form 4B ecosystem

- Fast: Prints model every 49 seconds.

- Versatile: Can use 15+ Formlabs and third party resins

- Intutive: Anyone can learn in 15 minutes

- Accurate: A perfect fit every time.

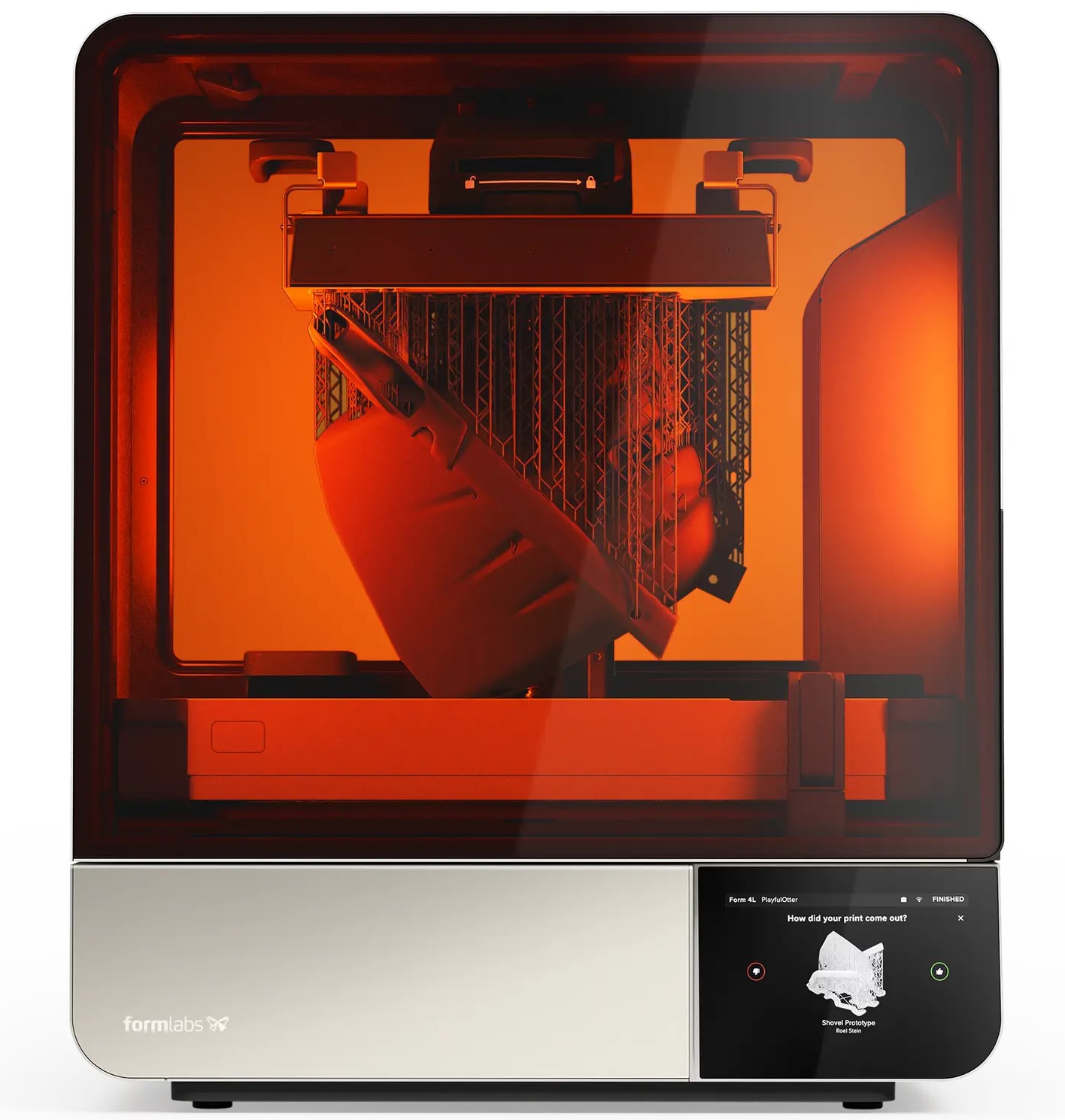

3. Formlabs Form 4L

Formlabs Form 4L is a blazing-fast large-format masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. Turn your biggest ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4L ecosystem.

- Fast: Full-size rapid prototyping

- Intuitive: Anyone can learn in 15 minutes.

- Large scale model: Solve big problem with large scale models.

- Reliable: Large format 3D printing You can depend on.

4. Formlabs Form 4BL

Form 4BL is a blazing fast large-format medical 3D printer that offers the most diverse materials library for healthcare. Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using the Form 4BL ecosystem.

- Blazing Speed: Same day turnaround for large or high-volume parts.

- Intuitive: Anyone can learn in 15 minutes.

- Big Parts: Innovate at scale without limitations.

- Reliable: Dependable production with stunningly accurate results.

5. Formlabs Fuse 1+ 30 W

Formlabs Fuse 1+ 30W is the best SLS 3D Printing platform chosen by more than half of the SLS users in the world Fuse 1+ 30 W SLS 3D Printer. Fuse 1+ 30W Designed for Maximum output and minimum waste this compact SLS 3d printer packs an industrial punch.

Unlock unprecedent print speeds and materials enablement to deliver truly rapid production in-house. Optimize Prints in One Click: Use free print preparation software, Preforms, to import 3MF, STL, or OBJ files, orient models, estimate print times and material usage, and monitor prints.

Preforms powerful SLS 3D printing algorithm automatically arranges models to increase throughput and reduce material waste by optimizing the packing density. Monitor and Manage Your Printer From Anywhere: Take control of production across multiple locations and machines.

Conclusion

Formlabs has set new standards in the 3D printing industry with its innovative SLA and SLS solutions. Formlabs user-friendly approach, advanced materials, and automation features make it a top choice for businesses and professionals looking for high-quality, reliable, and scalable 3D printing technology.