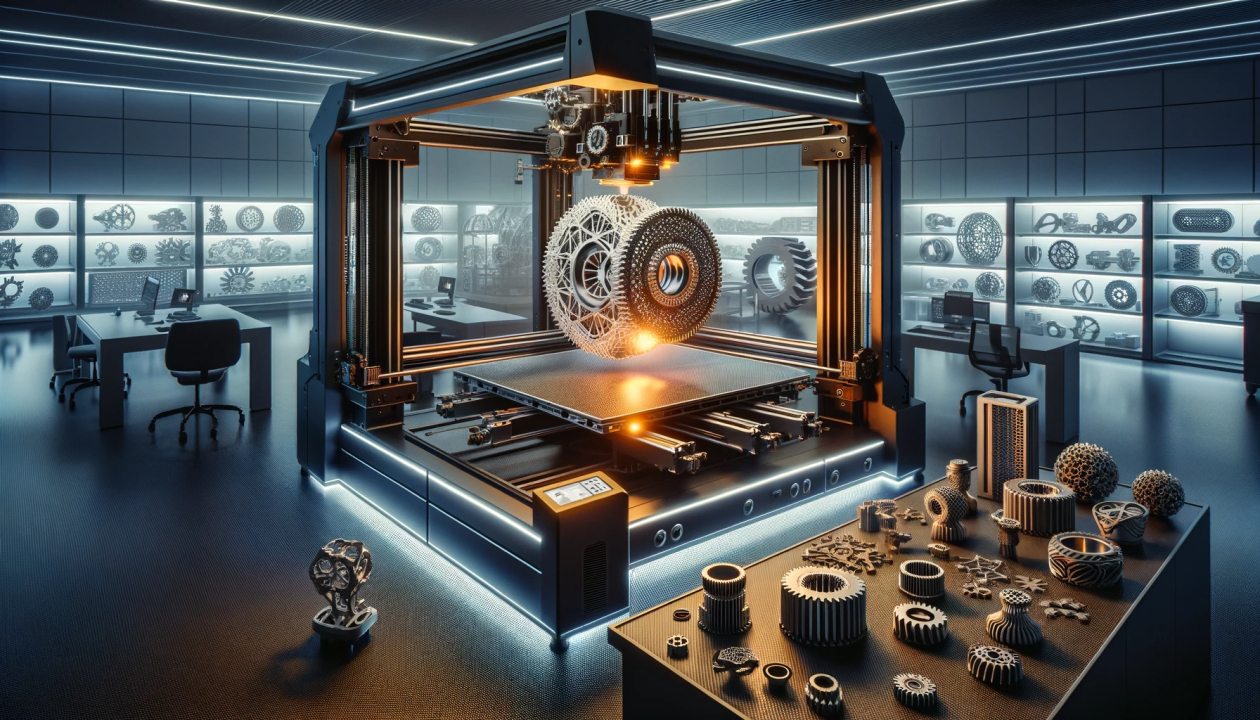

The manufacturing industry is witnessing a transformation like never before, thanks to the advent of 3D printing technology. Also known as additive manufacturing, 3D printing has introduced unprecedented levels of efficiency, customization, and innovation across various sectors. From prototyping to end-product manufacturing, this groundbreaking technology is reshaping how we conceptualize and create goods.

How 3D Printing Works

At its core, 3D printing involves creating three-dimensional objects by adding material layer by layer, guided by a digital design. The process begins with a CAD (Computer-Aided Design) model, which is sliced into thin cross-sections. The 3D printer then deposits material, such as plastic, resin, metal, or even bio-materials, in precise patterns to form the desired shape. This method contrasts with traditional subtractive manufacturing, which involves cutting away material to create a product.

Advantages of 3D Printing in Manufacturing

- Cost Efficiency: 3D printing eliminates the need for expensive molds and tooling, reducing setup costs significantly. Manufacturers can create complex designs without incurring additional expenses.

- Rapid Prototyping: Iterations can be produced quickly and affordably, allowing designers and engineers to refine products faster than ever before.

- Customization: The technology supports the creation of unique, tailor-made products for specific needs, making it ideal for industries like healthcare, where custom prosthetics and implants are in high demand.

- Material Efficiency: By using only the required material to build an object, 3D printing reduces waste, promoting sustainable practices.

- Flexibility in Design: Complex geometries that were once impossible to manufacture are now achievable, opening doors to innovative designs.

Applications Across Industries

- Aerospace: Lightweight and durable components are critical in aerospace. 3D printing enables the production of parts with optimized designs that improve performance and reduce weight.

- Healthcare: From dental aligners to surgical instruments and custom implants, 3D printing has revolutionized patient care by providing precise, patient-specific solutions.

- Automotive: Car manufacturers leverage 3D printing for rapid prototyping and producing parts with intricate designs that enhance vehicle performance.

- Consumer Goods: The fashion and jewelry industries are exploring 3D printing to create intricate designs, while companies like Nike and Adidas use it to develop innovative footwear.

- Construction: Large-scale 3D printers are now capable of producing entire buildings, reducing construction time and costs.

Challenges and Future Prospects

Despite its many advantages, 3D printing faces challenges such as limited material options, slower production speeds compared to traditional methods for mass production, and high initial investment costs for industrial-grade printers. However, ongoing advancements in materials, speed, and scalability are addressing these limitations.

The future of 3D printing is undeniably bright. As the technology becomes more accessible and affordable, its adoption will continue to grow across industries. Innovations such as multi-material printing, bioprinting, and advancements in metal printing are set to expand the horizons of what’s possible with additive manufacturing.

Conclusion

3D printing is more than just a manufacturing tool; it’s a catalyst for innovation, enabling businesses to reimagine their production processes and deliver value in new and exciting ways. By embracing this technology, industries can enhance efficiency, reduce waste, and push the boundaries of creativity. As we look to the future, 3D printing is poised to be a cornerstone of modern manufacturing, revolutionizing the way we design and build.

Products we offer at Ashtech 3D Innovations in Pune, Mumbai, Nashik, Aurangabad, Nagpur, Kolhapur, Goa, Belagavi, Vishakhapatnam, Guwahati, Chhattisgarh, Delhi, Vadodara, Faridabad, Bangalore, Thiruvananthapuram, Chennai, Hyderabad,

Zortrax FDM 3D Printer (M300 Dual,M300 Plus, M200 Plus), Formlabs SLA 3D Printer (Form 4, Form 4L,Form 4B, Form 4BL), Thor 3D Scanner (Calibry, Calibry Mini). FDM 3D Printing Services, SLA 3D Printing Services, SLS 3D Printing Services, MJF 3D Printing Services, Metal 3D Printing Services, Vacuum Casting Services , 3D Scanning Services, Reverse Engineering Services & All Type Of Prototyping Services.